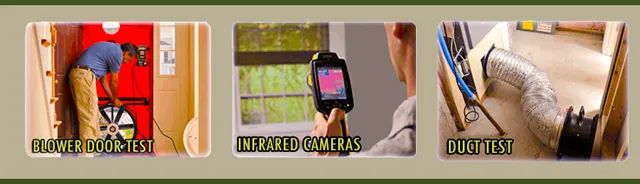

How We Test

During our Comprehensive Home Assessment (Home Energy Audit), we use special diagnostic equipment as shown in the photos below to assess exactly where and how much air is leaking from your home. You don’t have to spend hours in your basement, attic, and all the rooms in your home trying to find the source of the leaks, all of which may be hidden. We are trained experts in determining where the leaks are and how to fix them — safely and effectively, guaranteed.

» The Blower Door Test is a powerful fan that is mounted into the frame of an exterior door. The fan pulls air out of the house, lowering air pressure inside. The higher outside air pressure then flows in through all unsealed cracks and openings. Since leakier houses require more airflow to induce a given pressure difference, blower doors can measure the relative leakiness of a house. A blower door test will measure failures in air boundaries, failures that left uncorrected will continue to leak both air and dollars.

» Thermography uses specially designed infrared video or still cameras to make images (called thermograms) that show surface heat variations. This technology has a number of applications. Thermograms of electrical systems can detect abnormally hot electrical connections or components. Thermograms of mechanical systems can detect the heat created by excessive friction. We use infrared cameras as a tool to help detect heat losses and air leakage in building envelopes. In addition, Infrared scanning allows us to check the effectiveness of insulation in a building’s construction. The resulting thermograms help determine whether a building needs insulation and where in the building it should go. Because wet insulation conducts heat faster than dry insulation, thermographic scans of roofs can often detect roof leaks.

» Duct Blaster Test combines a small fan and a pressure gauge to pressurize a house’s duct system and accurately measure air leakage of the ductwork. This test is similar to a pressure test of a plumbing system and is performed at completion. There is only one way to find out if the ductwork has been properly sealed and that is to test it. Poorly sealed ductwork can negate all your HVAC technicians efforts as far as a installation of a new, properly sized HVAC unit, the original duct layout and design, tuning the equipment properly, etc. Your installer probably isn’t even aware that the ductwork is leaking. If you don’t test it, how would you know? Leaks are possible at any joint or seam in the system, from the air handlers right to the sheet-metal supply boots. Sheet-metal trunk ducts have a seam every 48 inches where they connect. Every collar attached to the trunk, every adjustable elbow, and even where flex duct connects to supply boots is a source for potential leaks.